Replacing the starter motor in a Honda Odyssey can be daunting for those unfamiliar with vehicle maintenance. However, with the proper guidance and tools, it becomes a manageable project that can save significant repair costs. This guide on Honda Odyssey starter motor replacement will walk through the necessary steps to ensure a successful replacement process.

Understanding the Starter Motor

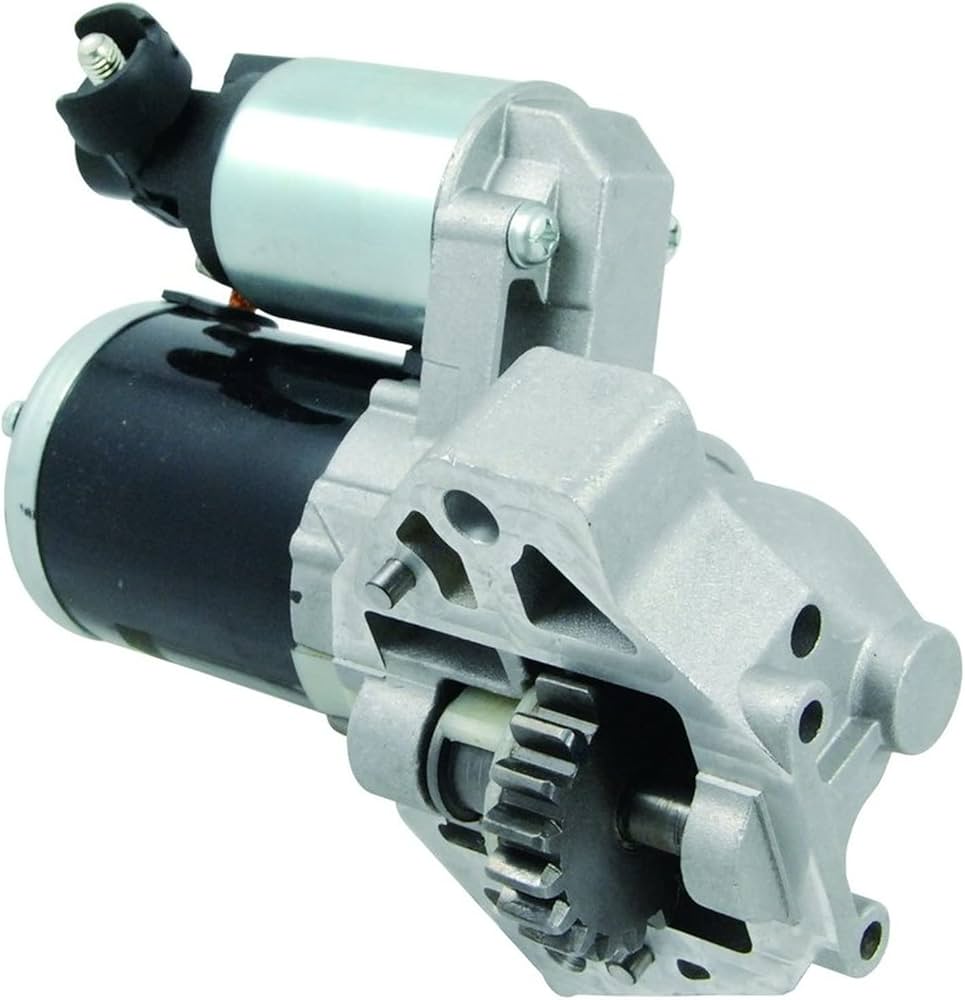

The starter motor is pivotal in initiating the engine’s operation by converting electrical energy into mechanical motion. It engages with the engine’s flywheel to spin it at a sufficient speed for combustion to commence.

Typically located near the engine’s bottom in a Honda Odyssey, accessing it may require maneuvering around other engine components. A malfunctioning starter motor can lead to difficulty starting the vehicle, necessitating prompt attention and replacement.

A faulty starter motor can significantly impact your Honda Odyssey’s performance and reliability. Recognizing the early signs of a problem can help you address the issue promptly, preventing further damage and ensuring a smooth driving experience.

Common Symptoms of a Faulty Starter Motor:

When you turn the ignition key, you may hear a clicking sound from the engine compartment. This indicates that the starter motor is engaging but struggling to turn the engine.

Engine Failure to Turn Over

If the engine fails to turn over when you attempt to start it, it’s a strong indication of a faulty starter motor.

Slow Cranking

The engine may crank slowly or with difficulty, suggesting that the starter motor is malfunctioning.

Inconsistent Starting

You may experience inconsistent starting, where the vehicle starts sometimes but not others. This can be a sign of a deteriorating starter motor.

If you notice any of these symptoms, addressing them promptly is essential to avoid more severe engine issues. A faulty starter motor can lead to a dead battery, difficulty starting the vehicle, and even prevent you from driving altogether.

Locating the Starter Motor

The starter motor in a Honda Odyssey is generally positioned near the transmission at the front of the engine. However, the exact location may vary slightly depending on the specific model year and engine configuration. To pinpoint the starter motor’s location accurately, it is crucial to consult your vehicle’s service manual.

The manual will provide detailed instructions and diagrams illustrating the starter motor’s position relative to other components. It may also indicate any necessary steps to access the starter motor, such as removing the air intake duct, engine cover, or other obstructions.

By carefully following the instructions in your service manual, you can confidently locate the starter motor and prepare for its removal or inspection. If you encounter any difficulties or are unsure about the process, you should seek assistance from a qualified mechanic to avoid potential damage or complications.

Disconnecting the Battery

Before working on the vehicle’s electrical system, it is crucial to prioritize safety and prevent potential hazards. One of the most important steps is to disconnect the battery. This will help avoid electrical shocks and damage to the vehicle’s electrical components.

To safely disconnect the battery, locate the negative terminal, typically marked with a “-” sign. Use a battery terminal disconnect tool or a wrench to loosen and remove the terminal from the battery post. Once the negative terminal is disconnected, detach the positive terminal, which is marked with a “+” sign. It is essential to disconnect the negative terminal first to prevent accidental short circuits.

Taking these precautionary measures ensures the electrical system is de-energized, making it safe to proceed with the Hon starter motor replacement. Safety should always be a top priority when working on your vehicle.

Installing the New Starter Motor

Position the new starter motor, ensuring proper alignment with the mounting holes. Securely bolt it to the engine block using a torque wrench to tighten the bolts according to the manufacturer’s specifications.

Carefully reconnect the electrical connections, confirming they are attached firmly and correctly. Ensure all components are positioned without any strain on the wires or connectors. Proper installation is crucial to ensure the optimal performance of the starter motor.

Required Tools and Materials For Honda Odyssey Starter Motor

Replacing the Honda Odyssey Starter Motor involves a set of tools to ensure a smooth and efficient process. Here are the essential tools you’ll need:

Socket Set and Spanners

Various socket sizes are required to securely remove and install the starter motor. Spanners may also be necessary for specific connections.

Jack and Axle Stands

To safely lift the vehicle and provide access to the starter motor, a jack and axle stand are essential. Ensure the vehicle is securely supported on the stands before proceeding.

Screwdrivers

Phillips and flathead screwdrivers may be needed to remove plastic covers or access additional components.

Replacement Starter Motor

A starter motor designed for the Honda Odyssey model year is crucial for compatibility and optimal performance.

Torque Wrench

A torque wrench is essential to ensure the bolts are tightened to the correct specifications. This prevents overtightening or under-tightening, which can lead to damage or improper functioning.

Work Light

A good work light helps provide better visibility in dimly lit areas, especially when working under the vehicle.

Container

A container or tray can keep track of removed bolts, nuts, and other small parts to prevent loss or misplacement.

Having these tools readily available allows you to streamline the replacement process and minimize the time spent on the task. Proper preparation with the right tools and materials will contribute to a successful and efficient installation.

Safety Precautions

Safety should be prioritized during vehicle maintenance tasks. Ensure the vehicle is parked on a level surface and engage the parking brake. Wearing gloves and safety glasses protects against potential hazards. Use jack stands to support the vehicle securely when working underneath. Proper lighting can enhance visibility, reducing the risk of accidents. Always follow manufacturer guidelines and consult the vehicle’s manual for specific safety instructions for the starter motor replacement.

Removing the Old Starter Motor

Once the battery is disconnected, unbolt the starter motor from the engine block and detach the electrical connections. Carefully label any wires or connectors to ensure they are correctly reinstalled. It can be helpful to take a photo for reference.

Pay attention to any additional brackets or components needing removal to access the starter motor. Utilize appropriate tools to avoid damaging any parts during the removal process.

Preparing the New Starter Motor

Before installing the new starter motor, it’s essential to conduct a thorough inspection to ensure its quality and suitability. Look for visible defects or damage, such as cracks, corrosion, or loose components. Comparing the new starter motor with the old one can help verify compatibility and ensure it will fit securely in the designated mounting location.

To facilitate smoother operation, lightly lubricate any moving parts of the new starter motor, including the armature, commutator, and brushes. Use a high-quality grease or lubricant specifically designed for automotive applications. Avoid excessive lubrication, as it can attract dirt and debris.

Proper alignment and preparation are crucial for successful installation and optimal performance. Ensure the new starter motor is positioned correctly about the flywheel or flex plate. Align the mounting holes and secure the starter motor using bolts or clamps. Tighten the fasteners to the specified torque specifications to prevent looseness or misalignment.

By following these steps and carefully inspecting and preparing the new starter motor, you can help ensure a smooth and successful installation process. A well-prepared starter motor is more likely to function properly and provide reliable service for years to come.

Reconnecting the Battery: Engine Starter Motor Honda Odyssey

Begin by reattaching the battery’s positive terminal, ensuring it is tightened securely to maintain a robust electrical connection of Engine Starter Motor Honda Odyssey. Follow this by connecting the negative terminal and checking for a firm attachment again. Proper reconnection is essential to restore the vehicle’s electrical system and allow the newly installed starter motor to function correctly.

To avoid accidental short circuits, it’s necessary to ensure no tools or materials are left near the battery area. Verifying the tightness of both terminals is crucial to prevent electrical issues and guarantee reliable performance. This step is vital for effectively completing the starter motor replacement process.

Testing the New Starter Motor

After replacing the Honda Odyssey starter motor, testing its functionality is crucial to ensure a successful installation. Here’s a step-by-step guide: Ensure the battery is securely connected and has a sufficient charge. Turn the ignition key to the “Start” position. The starter motor should engage promptly and crank the engine smoothly. Listen for unusual noises, such as grinding or clicking, that might indicate a problem.

The engine should start immediately and run smoothly. If the engine fails to start or there are irregular sounds, it’s essential to investigate further. Recheck all electrical connections, ensuring they are secure and corrosion-free. A loose or damaged connection can prevent the starter motor from receiving power.

Verify that the starter motor is securely mounted using the correct torque specifications. Loose mounting bolts can cause misalignment and prevent the starter from engaging correctly. Test the battery’s voltage and condition. A weak or faulty battery can hinder the starter motor’s ability to crank the engine.

Final Checks and Adjustments

Conduct a thorough inspection to confirm that all components are secure and properly installed. Check that no tools or materials have been left in the engine bay and ensure that all previously removed parts have been reattached correctly. Verify that the electrical connections are firm and that there are no loose wires or connectors.

Confirm that the vehicle starts smoothly and the starter motor operates without any irregular noises or issues. Making these final checks guarantees that the starter motor replacement is completed successfully, ensuring the vehicle’s reliability and performance.

Conclusion

Replacing the Honda Odyssey starter motor is a complex task that requires specialized knowledge and tools. It is advisable to seek professional assistance from a qualified mechanic to ensure proper installation and avoid potential damage to your vehicle. Investing in a high-quality Honda Odyssey Starter Motor and following recommended maintenance practices can prolong its lifespan and provide reliable performance. By recognizing the early signs of a problem and seeking professional assistance, you can ensure that your Honda Odyssey remains reliable and enjoyable.

FAQs

What are the signs of a faulty Honda Odyssey starter motor?

Common signs of a faulty Honda Odyssey starter motor include:

· Difficulty starting the engine

· Clicking or grinding noises when attempting to start

· Slow cranking speed

· Battery light coming on

How often should I have my Honda Odyssey starter motor inspected?

It is recommended that your Honda Odyssey starter motor be inspected as part of your regular vehicle maintenance routine. This typically includes a visual inspection for signs of wear, corrosion, or damage. The frequency of inspections may vary depending on your vehicle’s age, mileage, and driving conditions.

What is the cost of replacing a Honda Odyssey Starter Motor?

Replacing a Honda Odyssey Starter Motor can vary depending on the specific model year, labor costs, and the choice of parts. Obtaining quotes from multiple mechanics to compare prices and find the best deal is advisable