Metal barcodes have revolutionized industrial operations by providing durable and reliable tracking solutions. However, the reflective nature of metal surfaces can pose challenges for barcode scanners, potentially leading to inaccurate data capture and operational inefficiencies. To overcome these challenges, a comprehensive understanding of metal types, barcode design, and advanced scanning technologies is essential.

The Impact of Metal Type on Barcode Scannability

Different metal types exhibit varying levels of reflectivity and surface texture, influencing barcode scannability:

-

Stainless Steel: A popular choice for industrial applications, stainless steel’s reflective surface can hinder barcode scanning. To improve scannability, consider:

- Deep Etching: A deeper etch can increase contrast and improve barcode readability.

- Matte Finish: Applying a matte finish to the metal surface can reduce reflectivity and enhance scannability.

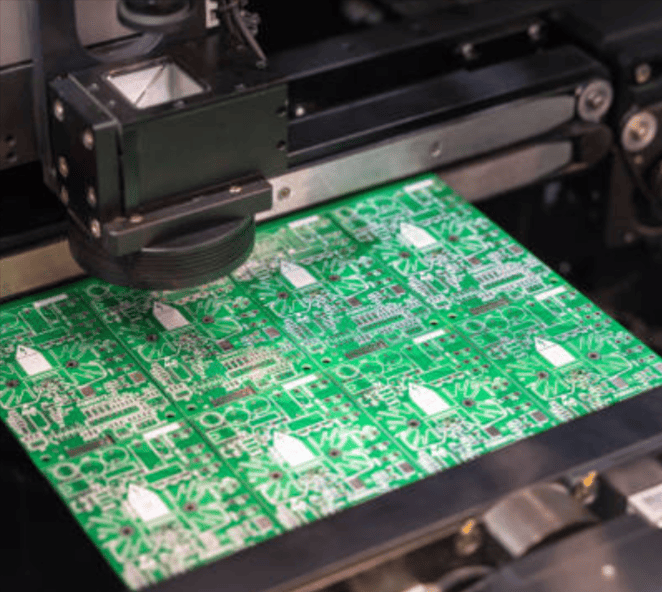

- High-Quality Barcode Printers: Using high-quality barcode printers can ensure accurate and durable barcode markings.

-

Aluminum: Lightweight and corrosion-resistant, aluminum is commonly used in various industries. However, its smooth surface can also cause scanning issues. To improve scannability, consider:

- Etching Depth: A deeper etch can provide better contrast and improve scannability.

- Anti-Reflective Coatings: Applying anti-reflective coatings to the metal surface can reduce glare and improve barcode readability.

- High-Contrast Barcodes: Using high-contrast barcode designs can enhance visibility, especially in challenging lighting conditions.

-

Brass: While less common in industrial applications, brass can be used in certain scenarios. Brass can be more challenging to etch than other metals due to its softer surface. To improve scannability, consider:

- Laser Etching: Laser etching can produce high-quality, durable barcodes on brass surfaces.

- High-Contrast Inks: Using high-contrast inks can improve barcode visibility.

- Careful Handling: Avoid scratching or damaging the barcode surface, as this can impact scannability.

Advanced Scanning Technologies for Metal Barcodes

To address the challenges posed by metal surfaces, advanced scanning technologies have been developed:

- High-Performance Metal Barcode Scanners: These specialized scanners are designed to handle the reflective properties of metal surfaces. They often employ advanced imaging techniques, such as laser scanning and camera-based scanning, to improve scanning accuracy.

- Lighting Techniques: Proper lighting can significantly impact barcode scannability. Using diffused lighting can help reduce glare and improve contrast.

- Barcode Design Optimization: Adhering to barcode standards and using high-quality barcode design software can ensure optimal scannability.

- Barcode Verification: Regularly verifying the quality of etched barcodes can help identify and address potential issues before they impact operations.

Additional Considerations for Optimal Scannability

- Barcode Placement: Consider the location of the barcode on the metal surface. Avoid placing barcodes in areas prone to wear, tear, or corrosion.

- Environmental Factors: Extreme temperatures, humidity, and dirt can affect barcode readability. Protective coatings or enclosures can help mitigate these factors.

- Scanner Maintenance: Regular maintenance of barcode scanners, including cleaning and calibration, can ensure optimal performance.

- User Training: Proper training of operators on barcode scanning techniques and troubleshooting can minimize errors and maximize efficiency.

By carefully considering these factors and implementing appropriate strategies, businesses can ensure accurate and efficient scanning of metal barcodes, improving overall operational efficiency and productivity.

By embracing these emerging technologies, businesses can unlock the full potential of metal barcodes and drive innovation in their operations.