In today’s modern homes, washing machines are no longer a luxury but a necessity. These efficient appliances save time, energy, and effort in completing one of the most tedious household chores. However, behind the smooth operation of every washing machine lies a critical component known as the Printed Circuit Board (PCB). The PCB is the brain of your washing machine, coordinating its various functions and ensuring it runs seamlessly. In this post, we delve into what a washing machine PCB is, how it works, and why it is essential to the appliance’s operation.

What Is a Washing Machine PCB?

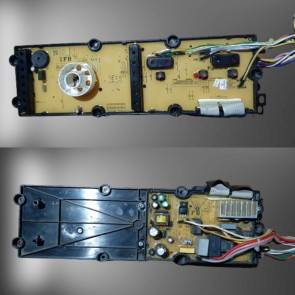

The Printed Circuit Board (PCB) is an electronic circuit board that controls and regulates the washing machine’s operations. It houses various electronic components, including resistors, capacitors, transistors, and microcontrollers, all interconnected to perform specific tasks. The PCB acts as the central processing unit (CPU) of the washing machine, receiving signals from different sensors and executing the appropriate commands.

How Does a Washing Machine PCB Work?

The washing machine PCB functions as the command center of the appliance. Here’s a breakdown of its role:

-

Signal Processing: The PCB receives input signals from various sensors, such as the water level sensor, temperature sensor, and door lock sensor. These signals provide real-time data about the machine’s status.

-

Program Execution: Based on the selected wash cycle and sensor inputs, the PCB processes the information and executes the program. It determines the sequence of operations, including water intake, detergent dispensing, drum rotation, and water drainage.

-

Motor Control: The PCB controls the washing machine’s motor, adjusting its speed and direction as required by the selected program. This ensures optimal cleaning performance.

-

Safety Mechanisms: The PCB is equipped with safety protocols to prevent malfunctions. For instance, it can detect overheating, overloading, or an unbalanced load and take corrective actions to protect the appliance.

-

User Interface Control: The PCB manages the display panel and buttons, allowing users to select and monitor wash cycles easily.

Common Issues with Washing Machine PCBs

Despite their importance, washing machine PCBs can encounter issues due to various factors, such as power surges, moisture, or wear and tear. Some common problems include:

-

Erratic Behavior: The machine may not respond to commands or display error codes.

-

Failure to Start: A damaged PCB may prevent the machine from starting altogether.

-

Inconsistent Performance: Faulty components on the PCB can lead to incomplete or inefficient wash cycles.

Maintaining and Replacing Washing Machine PCBs

To ensure the longevity of your washing machine’s PCB, follow these maintenance tips:

-

Use a Voltage Stabilizer: Protect the PCB from power surges by installing a voltage stabilizer.

-

Keep the Machine Dry: Avoid exposing the machine to excessive moisture, as it can damage the PCB.

-

Regular Servicing: Schedule periodic maintenance checks to identify and address potential issues early.

If your washing machine PCB is damaged beyond repair, replacing it with a genuine part is essential. Consult a professional technician to ensure proper installation and compatibility with your machine model.

Conclusion

The washing machine PCB is an integral component that powers and controls the appliance, ensuring it operates efficiently and safely. Understanding how it works and maintaining it properly can extend the lifespan of your washing machine and prevent costly repairs. The next time you load your laundry, take a moment to appreciate the technology working behind the scenes, making your life easier.

Лучшие аркадные игры в казино

аркада игровые arkada casino .

http://u-fitness.ru – кухни, которые подчеркнут вашу индивидуальность.

https://www.arzamas-sauna.ru – ваш партнер в создании стильных и функциональных кухонь.

https://arzamas-sauna.ru/ – кухни, созданные с вниманием к деталям.

купить кухню в екатеринбурге – большой выбор моделей по выгодным предложениям.

http://www.u-fitness.ru – уют и комфорт для вашей семьи.

http://www.u-fitness.ru – ваш партнёр в выборе идеальной кухни.

sunnyholiday.ru/ – Профессиональная фотосъемка товаров с доставкой лучших результатов.

съемка ювелирных изделий – Изящные фотографии, подчеркивающие красоту и детали украшений.

molpit.ru/ – воплощаем ваши идеи в реальность.

http://www.nemakrame.ru – качественные кухни, созданные с любовью и вниманием к деталям.

https://www.nemakrame.ru/ – широкий выбор решений для стильных кухонь.

предметная фотосъемка товаров – Профессиональный подход для вашего интернет-магазина.

предметная съемка москва – Профессиональная съемка товаров в Москве для рекламы и маркетинга.

https://ftbabrau.ru – кухни, созданные для комфорта и вдохновения.

https://www.molpit.ru – ваш надежный партнер в создании идеальной кухни.

http://www.molpit.ru – все для того, чтобы ваша кухня стала сердцем дома.

http://www.bagroo.ru – Откройте сайт для детальной информации о профессиональной фотосъемке товаров.

https://arzamas-sauna.ru/ – кухни, созданные с вниманием к деталям.

ftbabrau.ru – качественные кухни, которые подчёркивают ваш стиль.

заказать кухню – ваш идеальный выбор для создания уютного кухонного пространства.